Building a data ecosystem to help the semiconductor industry focus time and resources where it matters most.

Athinia™ provides a secure data analytics platform for collaborating on relevant information from material suppliers and device makers.

The Challenge

We’re experiencing a time of rapid growth and increased demands

Leading-edge semiconductor manufacturing processes are so sensitive that traditional quality control and supply management practices are no longer sufficient to maintain high-yielding integration flows. The rapidly increasing number of process variables requires smart and scalable data and analytical capabilities. To remain competitive, companies need to focus time and resources on the parameters that matter most.

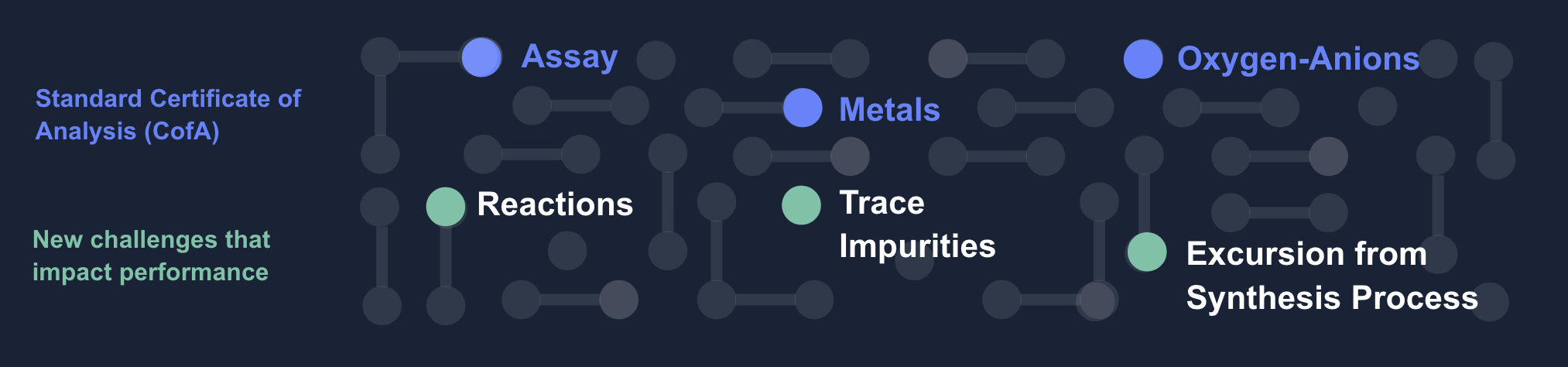

Parameters not captured in CofA account for >60% of variability in manufacturing *

* Based on exemplary use case

Smart data reduces quality deviations and helps focus resources on parameters that matter most.

Current state:

Traditional statistical analysis

Every parameter is analyzed separately; some correlations and interactions between parameters are potentially unaccounted for.

Today, solving simple manufacturing problems requires assessing interactions between parameters, requiring more advanced analytical tools.

Future state:

Multivariate analysis with Athinia

Data sharing allows all parameters to be correlated in one multivariate analysis; relevant parameters are identified that would have been ignored in traditional analysis.

The Solution

Our smart data collection and collaborative analytics ecosystem helps drive smarter business decisions

It starts with the three A's:

Device Makers and their Material Suppliers

Aggregate

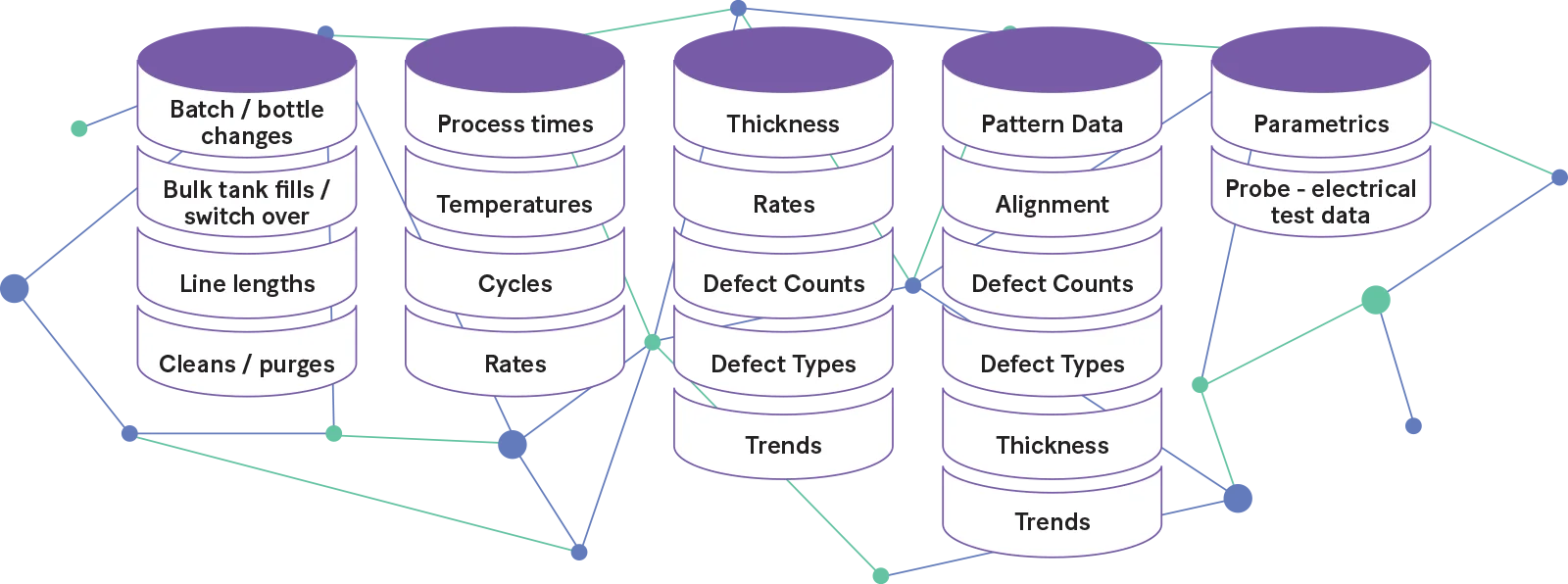

Gather relevant material, in-process and manufacturing data from within and across companies into a single platform so it can be easily analyzed.

Analyze

Run multivariate analysis to identify key parameters and opportunities to improve performance.

Act

Take action based on the insights identified and put resources where it really matters to drive performance.

Athinia’s™ easy and secure data exchange helps ensure participants can share an unprecedented amount of performance related data

Security

Built with the highest levels of data security and privacy.

Athinia™ is powered by Palantir’s Foundry platform, leveraging their strict data security standards. Our cloud infrastructure and operations are trusted by many of the world's most sensitive institutions to protect their data.

Learn more about data security at Athinia™The Benefit

Benefits of secure, collaborative data sharing

Allow for integrated analysis and control of data by device makers and material suppliers

Provide holistic view and predictions of in-fab performance

Break silos and increase efficiency to solve the most pressing semiconductor manufacturing challenges

For Device Makers

Share and analyze the data that matters with your suppliers to help improve yield, efficiency and performance

For Material Suppliers

Focus on the parameters that matter most to material performance and put your effort where it really counts

Case Studies

CASE STUDY

Shift from reactive to proactive improvement of “first-time right” with secure data sharing

Oftentimes one specific criteria doesn’t meet fab specification limits, and raw material pre-conditioning is a month-long process that can delay customer needs.

CASE STUDY

Save time and free up resources with integrated data access

Batch quality analysis often requires a lengthy data gathering processes involving many different systems. The root cause investigation is typically an intensive, manual processes which can take many days to complete.